How to Calculate the Cost of Your Upcycled Designs

In the last few weeks, things have picked up significantly for me. I just got back from Doha, Qatar where I was there as an Arts Envoy through the US Embassy. While I was there, I presented my NOORISM line in a fashion show, gave a few lectures on sustainability and hosted an Upcycled DIY Workshop. I'm also getting great sales feedback on my NOORISM pieces, and I am planning out more production and new designs.

With inflation up right now and retail being in a weird place due to the pandemic, I am being very careful and strategic with determining my prices and deciding what to produce.

These days, I sell mainly on the NOORISM website, and at a shop in NYC called The Canvas as well as select pop ups. The Canvas is unique in that they are really a brand partner and not a traditional retail store. I can choose to give them whatever merchandise I would like to sell and in return, they merchandise it, take care of running the store and they take a percentage of the sale.

Costing can be really intimidating and scary especially when you're just starting out. Most designers struggle with the balance of running a business and being creative within the business. When it comes to costing your designs, I recommend simplifying your process.

There is no one set way for brands to determine pricing or cost structure and certainly producing larger quantities brings down the cost of everything!! This is one of the challenges of being small. If I produce too much quantity, it could take a very long time for the merchandise to sell but if I keep my quantities small, I won't make as much money or I will have to raise my prices!! This is a dilemma that most small designers face and sometimes becomes even more challenging when working with upcycled materials.

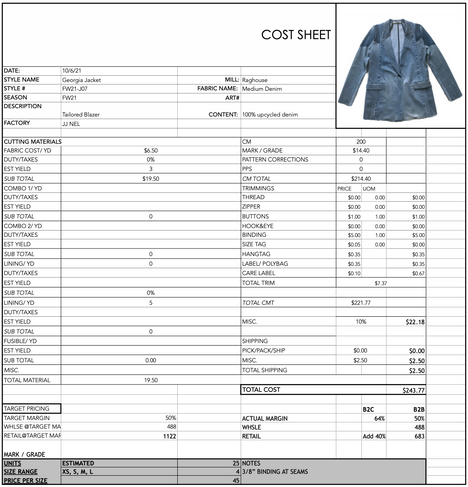

The most important part of determining your costing is to accurately calculate how much money you will spend making each piece.

You will need to account for the cost of materials, the cost of cutting and sewing, the cost of grading your pattern into multiple sizes, trims, labels and hangtags and any other element that goes into making your garment or accessory. Once you have added up all the materials and elements, I recommend adding 10% for miscellaneous expenses. Things don't always go as planned during the production process and therefore it's important to leave a margin of error.

Now that you know your actual production cost, you can double that number to get your wholesale price.

Main factors that Affect Garment Costing:

1. Materials:

When using second hand garments as materials, you should calculate the cost per piece it takes to produce 1 style. When using dead stock fabric, you should calculate the cost per yard or meter.

2. Cost of Cutting and Sewing

The manufacturer will give you this price based on their calculations after they make a sample or based on taking a careful look at your sample. Prices do vary depending on the manufacturer so its always a good idea to shop around and get several quotes and test their quality by having them make a sample before choosing who to give the order to. The cost of manufacturing also depends on where you are producing. Domestic production is usually more expensive.

If you are doing your own sewing, make sure you accurately calculate your hours and quantify the cost based on what you would have to pay someone else to do it.

3. Grading

Grading is the process of creating a range of sizes for a single apparel style. The purpose of grading is to properly fit a pattern into a range of sizes. The cost of grading will be determined by how many sizes you need and how complicated the pattern is.

4. Quantity

The quantity of the order also helps determine the price for cutting and sewing. The more pieces you produce, the less expensive each piece will be.

5. Complexity of the Garment

How complicated is your style? The number of pattern pieces and the type of seam and hand finishes will also impact the price.

6. Trims and Notions

The more elements that are in the garment, the more expensive it will be. The cost of zippers, buttons, lining and embellishment will all impact the cost.

7. Labels and Packaging

The cost of labels depends on the size and materials you are choosing, and the amount of labels ordered plays a significant role too.

8. Profit Margins of the Organization

This is basically what you earn when you sell your garment. This amount includes your own pay, helps your business stay afloat and invest into developing new styles. Most fashion businesses aim for a 50% margin.

9. Other Expenses

Come up with the amount that helps you pay the bills like rent, employees salaries, utilities and include it in the cost of your final product if you have these expenses.

I recommend adding 10% for miscellaneous expenses. Things don't always go as planned during the production process and therefore it's important to leave a margin of error.

If you are looking for more guidance on starting and growing your own upcycled brand, I recommend checking out my Upcycle Design Masterclass where I have put together a whole program to help you get started including a costing sheet template.

FREE GUIDE to Finding Upcycled Materials

How to Find Upcycled Materials and NOT Get Lost in the Process

"Noor's List": 25 + sources from around the world to find UPCYCLED materials

Enter your email to receive your FREE DOWNLOAD